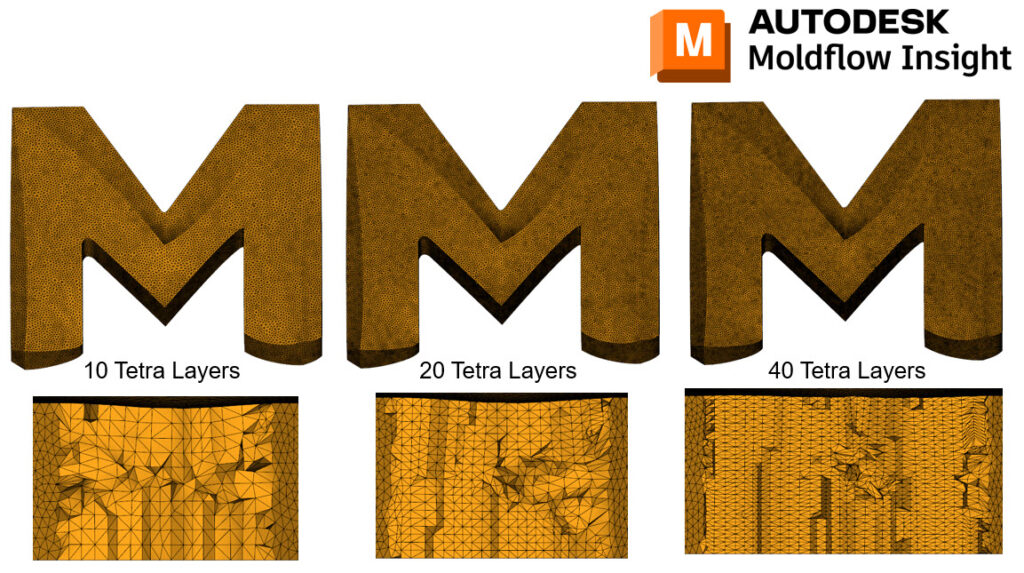

How many tetras to use through the thickness in Moldflow Insight?

There are 10 tetras by default in a 3D mesh in Moldflow Insight.

I was on a call with another Autodesk Moldflow Expert and they said they were having issues meshing a part to 3D. My buddy said, “It won’t mesh with 40 tetras through the thickness so I am trying 38”.

I almost fell off my chair.

I think the most I have ever tried was 12-16 and that was 5 years ago.

Now to their defense, they were trying to study non-uniform shearing in a 3D cold runner. We normally state in Moldflow training that you should use 20 tetras through the thickness for those scenarios. Our Moldflow developers also suggest additional tetras through the thickness for fiber analysis (12-16 should suffice). The moral of this story is that there might be times when we need more tetras through the thickness, but not for all applications.

Bonus tip – if you do need more tetras through the thickness, you might want to ensure your surface mesh is more refined as well.

How many tetras through the thickness do you use?