How to determine how much pressure is acceptable in your Moldflow simulations?

Let’s talk about Pressure.

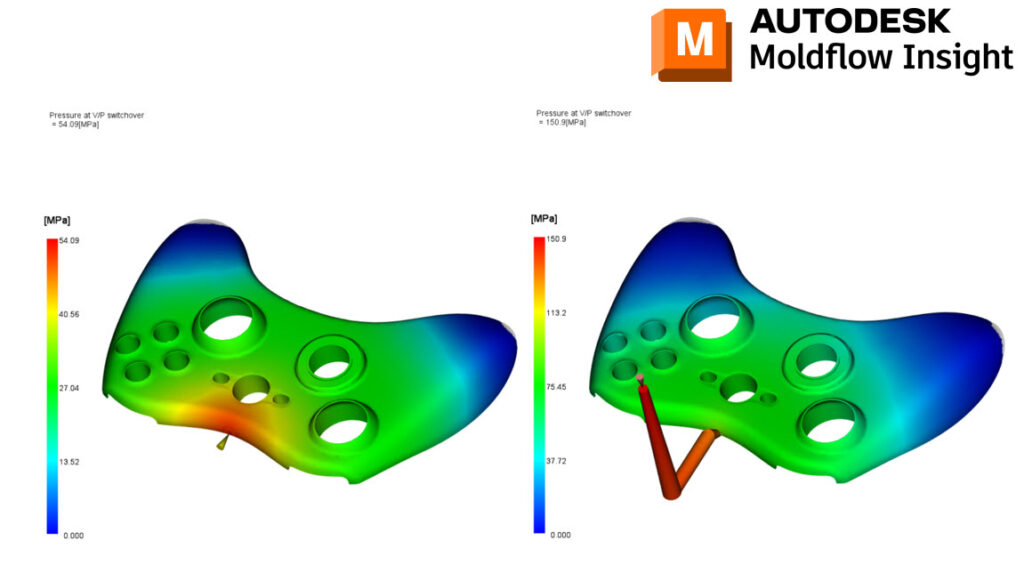

When I am running Moldflow on a part only analysis, I like to use about 50% of the available pressure. If you are using the default injection molding machine in Moldflow, this has maximum plastic pressure of 180 MPa (~26,000 psi).

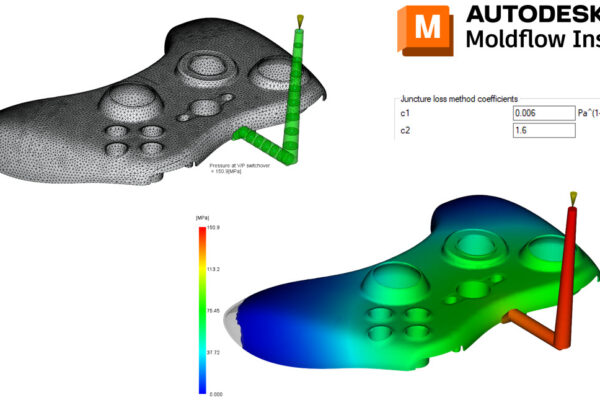

Once I add a runner system, I usually try to only use 75-85% of the available pressure. This leaves me some available pressure without maxing out the machine.

How do you determine how much pressure is acceptable in your Moldflow simulations?