How to determine the optimal filling control with runners?

Selecting the correct injection time can be critical for avoiding short shots and preventing quality issues like burn marks.

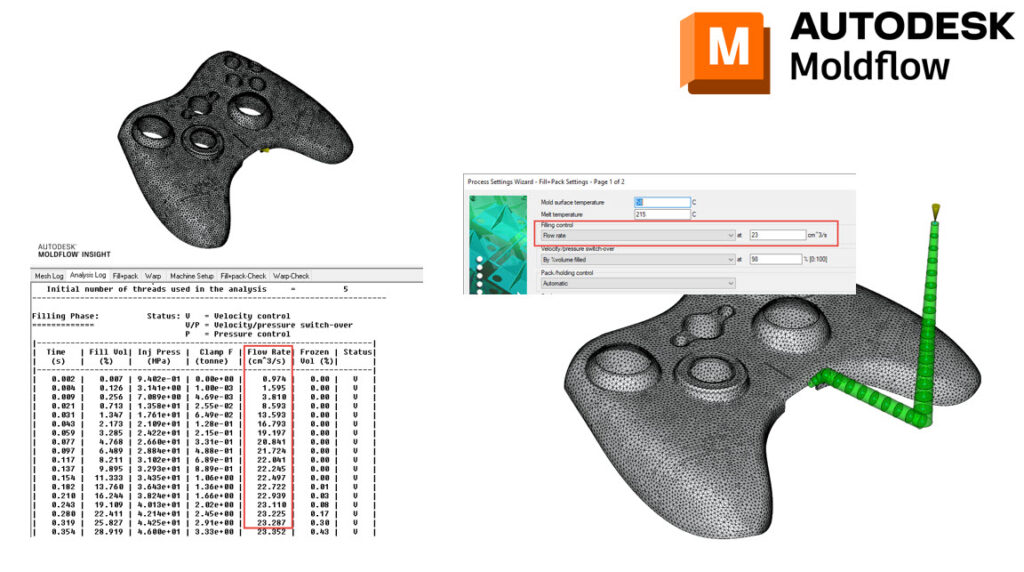

I typically use Molding Window to establish my part-only injection time. I would then run an actual Filling analysis to verify my injection time.

Once I add a runner system, I can’t use the same injection time since I have added additional plastic volume to the system. Assuming my part-only Filling analysis looks acceptable, I would then go to the log file and look at the calculated flow rate. This flow rate will become my new filling control with my part + runner model.

How do you determine the optimal filling control with runners?