How to mesh parts that have CAD issues!

Have you ever had a part that will not mesh in Moldflow Insight?

I had two of those parts last week. The first part I was able to fix in Fusion using the Solid – Inspect – Validate command or unstitching, creating surfaces, and re-stitching. Sometimes simply passing a model through Fusion will be enough for the CAD mesher to work properly.

The 2nd part failed to mesh even after passing through Fusion, using the Validate command, and repairing surfaces.

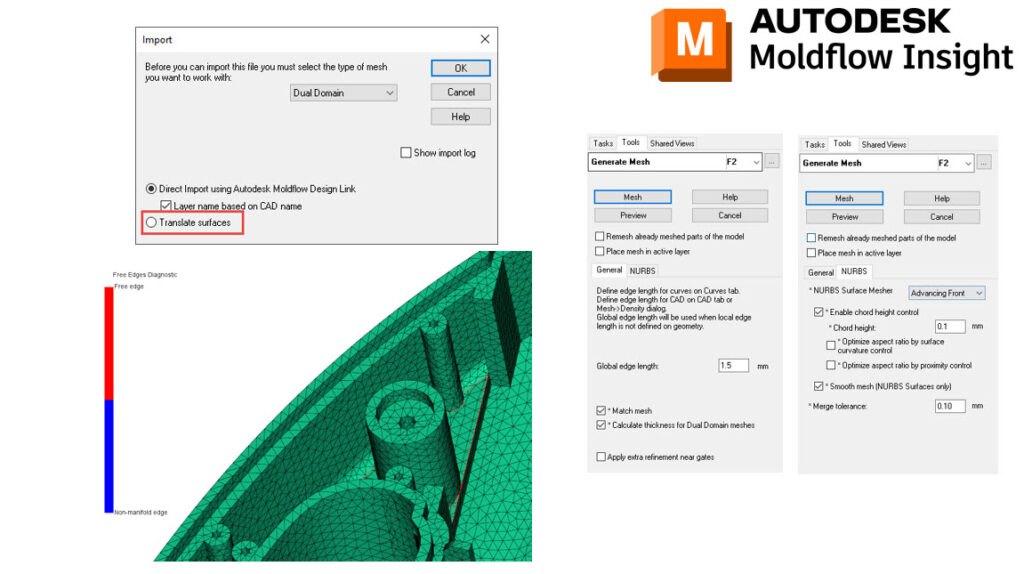

In 2023, my colleague (Joseph Huegel) and I noticed a Translate Surfaces option. This appears to use the older global edge length and NURBS surfaces to mesh the part. It also will separate the surfaces, mesh the clean ones, and avoid any that have issues. There will be some cleanup required however the use of Fill Hole, Stitch Free Edge, and Merge Nodes should make this easy.

I would still prefer the default CAD mesher but this Translate Surfaces might work if everything else fails.

How do you mesh parts that have CAD issues?