How to take Moldflow results to integrative FEA via Helius and Digimat!

I once explained the integrative Moldflow-Helius-FEA (or Digimat) method to one of my training attendees. They looked at me and stated that every FEA she has ever completed on an injection molded plastic part had been incorrect.

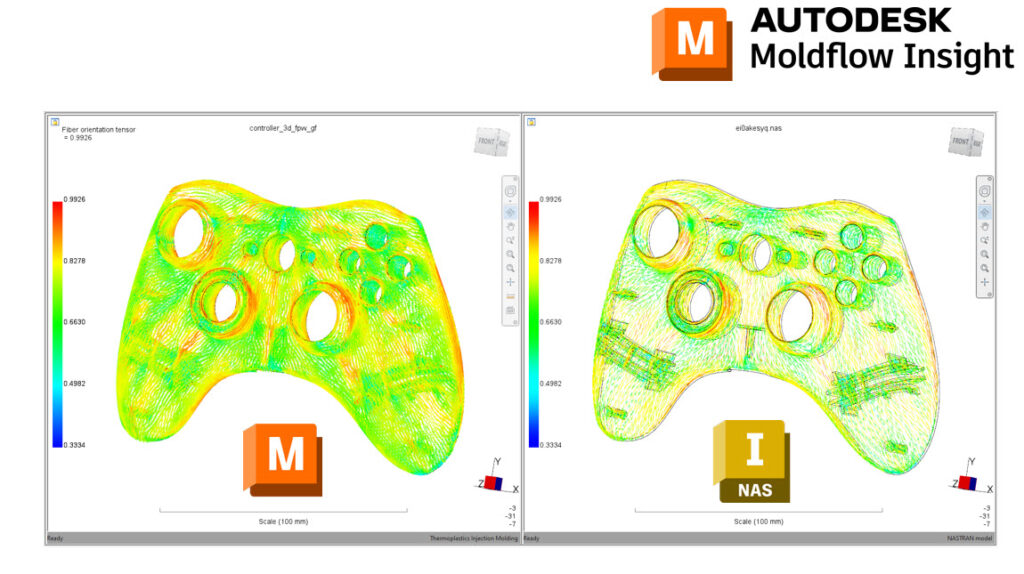

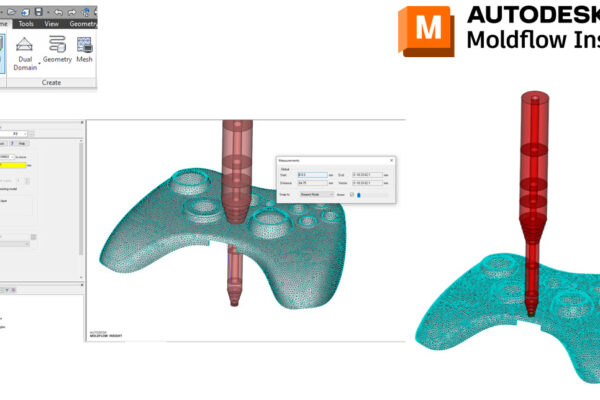

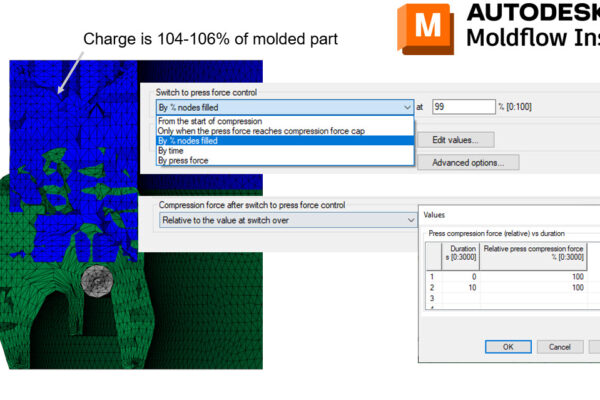

If you are running fiber-filled materials in both Moldflow and FEA, you should be considering the impact fiber orientation and weld lines have on your FEA. You can run your Moldflow as normal (be sure to be in 3D mesh and turn on weld strength analysis, Advanced – Solver Parameters- Edit – Interface – Weld Surface Strength Analysis). You can then take your FEA mesh (Nastran or ANSYS) and combine them in Helius Advanced Material Exchange (AME) or Digimat. This will map fiber orientation, stress, and weld lines from Moldflow to your FEA mesh.

Finally, you can run the mapped FEA mesh to see how fiber and weld line locations/strengths will change your FEA results. Read more about integrative simulation and how we can support you through services here.

Have you ever tried taking Moldflow results to FEA via Helius AME or Digimat?