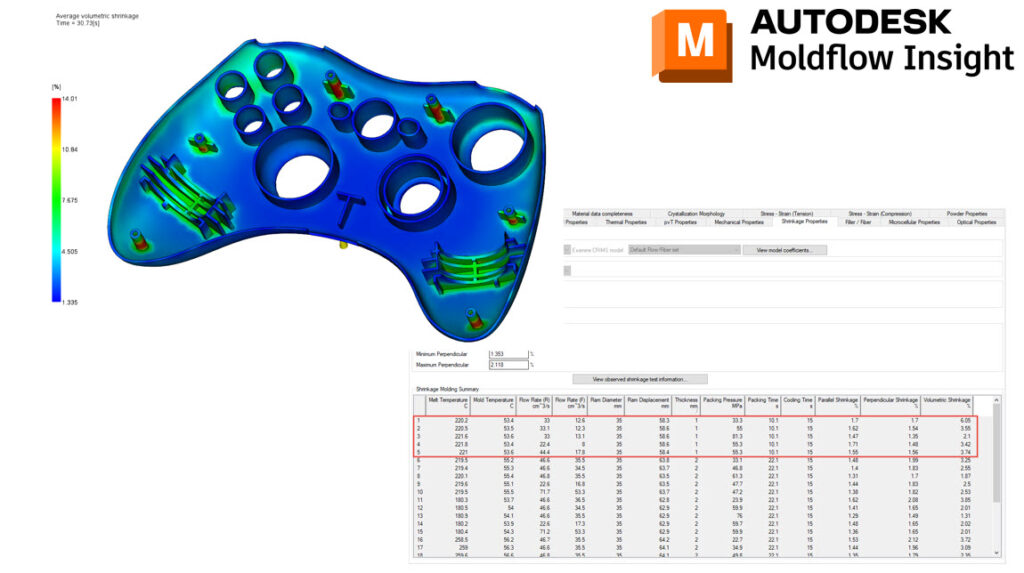

How to determine the maximum amount of volumetric shrinkage?

How much volumetric shrinkage is too much?

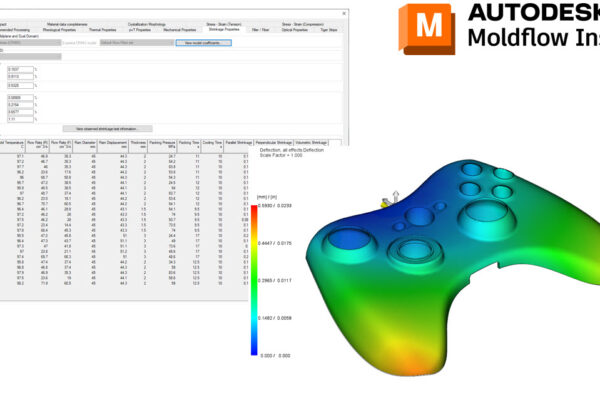

Volumetric shrinkages will vary based on our materials (amorphous vs semi-crystalline) and our wall thicknesses. Ideally, the volumetric shrinkage range should be low (~2%). Variations in shrinkages will lead to warpage headaches.

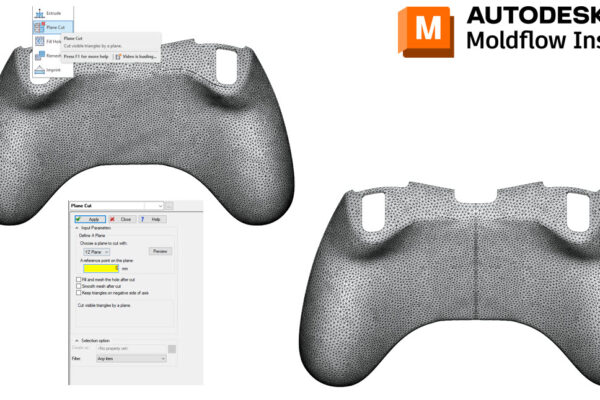

You can use the CRIMS data from a material card to see if your predicted volumetric shrinkages are close to our molded CRIMS plaques. I would suggest finding the closest thickness and process variables that align with your application. If your values are close to the CRIMS data, you might be safe. If your values are higher than the CRIMS data, you might need to adjust the part design or process.

If you have a material card that does not contain CRIMS data, you can have materials measured through us. Please send us a contact request using our contact details below.

How do you determine the maximum amount of volumetric shrinkage?