Why the Molding Window Analysis can be useful!

Today’s lesson is brought to you by my favorite Moldflow analysis: Molding Window!

I have to admit, this was not always my favorite. I remember learning about this analysis in college. I thought it looked weird, it didn’t look like “Moldflow”, and I was sure that I would never use this tool in the future.

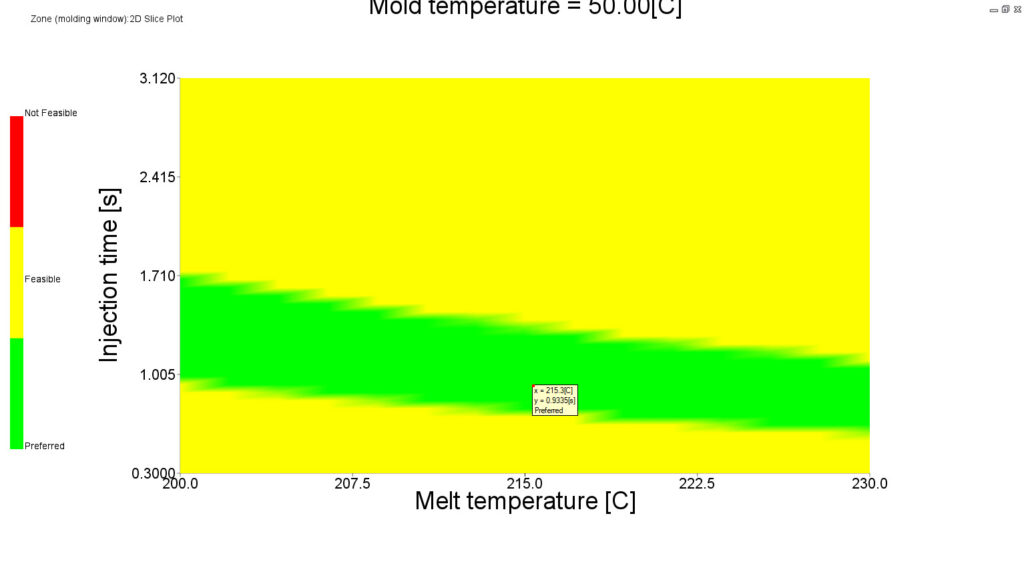

Look at me all grown up! Molding Window saves me time (they take about 2-3 sec to solve) by helping me determine my process settings.

You need a mesh (Midplane or Dual Domain) and an injection cone. I adjust my Molding Window default settings slightly but that is covered in our training courses. This helps me determine my Mold/Melt temperature, injection time, and cooling time.

Even if I eventually run a 3D mesh, I still run a Molding Window on a Dual Domain copy.

Is Molding Window perfect and going to solve all your problems? No, but if you are in Moldflow and looking to pick your process settings, I highly suggest running a Molding Window!