How to correctly interpret the Melt Flow Rate (MFR)!

I do not like Melt Flow Rate (MFR) data.

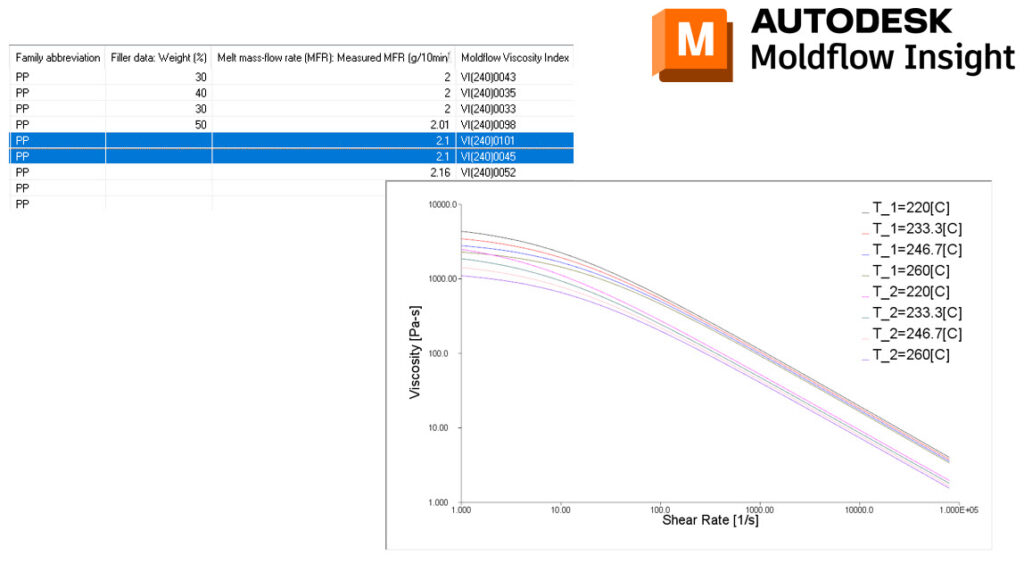

Let me rephrase, I do not like using MFR data to select materials within Moldflow. MFR data is an easy test but does not see the same high shear rates we see within injection molding. I prefer to use the Moldflow Viscosity Index. This provides you with information on the temperature of the test and actual viscosity measurements.

These two materials have the exact same MFR data however one has a viscosity measurement of 45 and the other 101. These materials will not have the same pressure even though the MFR data is the same.

How do you compare materials in Moldflow?