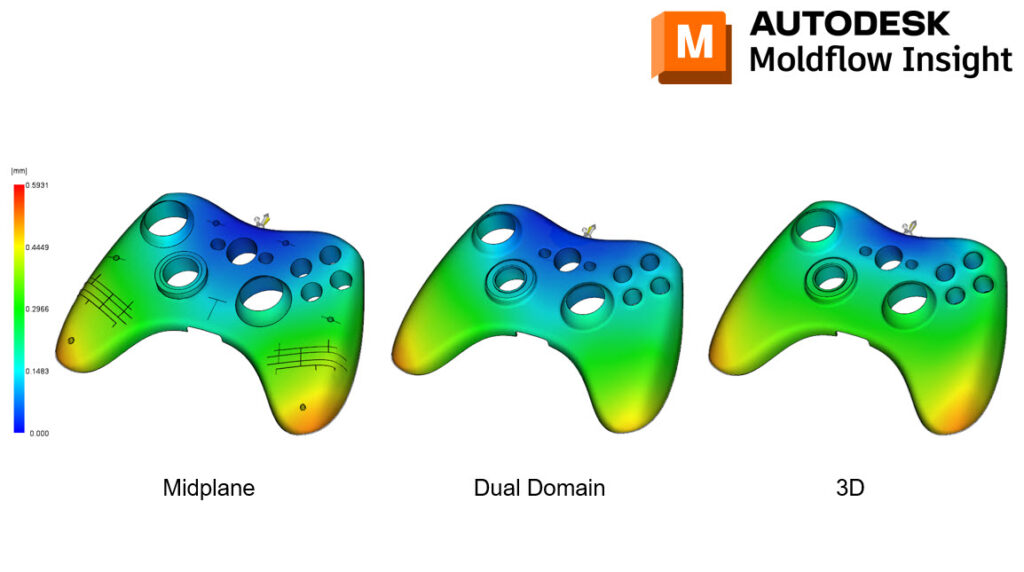

Which mesh type should be used in Moldflow?

I often get asked, which mesh type should be used in Moldflow?

I review the part geometry, analysis objective, and material card to determine my mesh type.

If I have a very large, thin-walled part, and I am concerned about unstable loading – I will run Midplane if CRIMS data is available.

If I have a thin-walled part that is box-shaped, I will most likely choose Dual Domain (again assuming CRIMS data is available) and turn on Corner Effects.

If I have complex part shapes or if my mesh match is poor, I will run 3D. I would also look to ensure the Mechanical data is tested since this is used in 3D warp calculations.

What mesh types do you typically use?