Why fiber-filled materials can be useful?

As requested, today’s topic is all about fiber-filled materials!

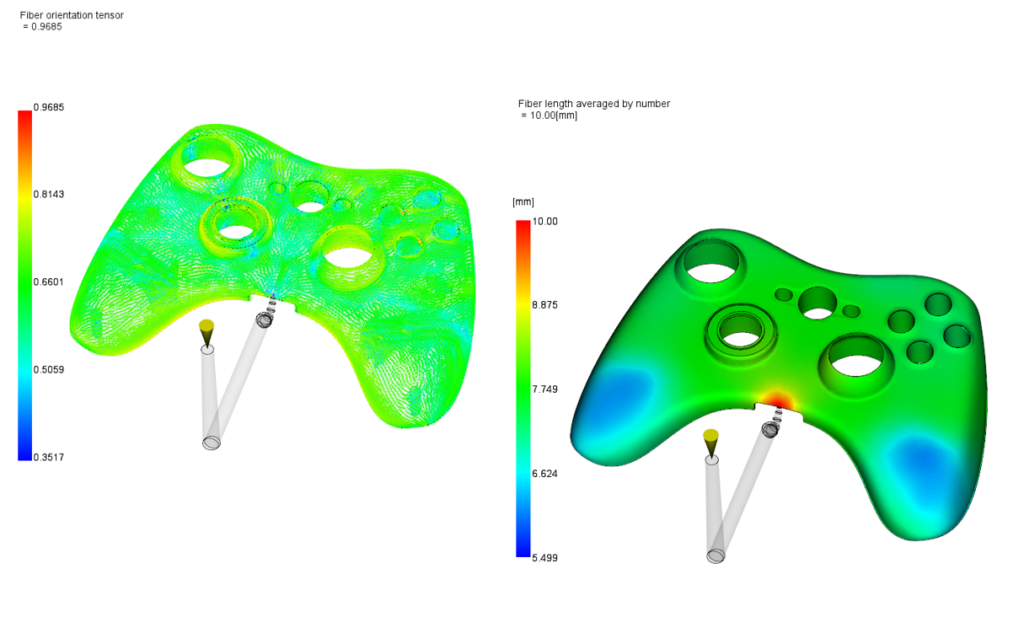

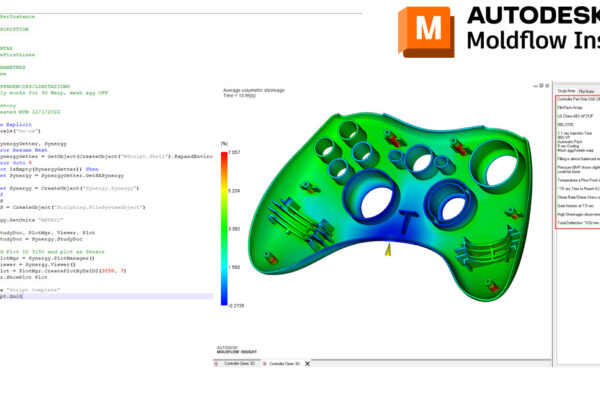

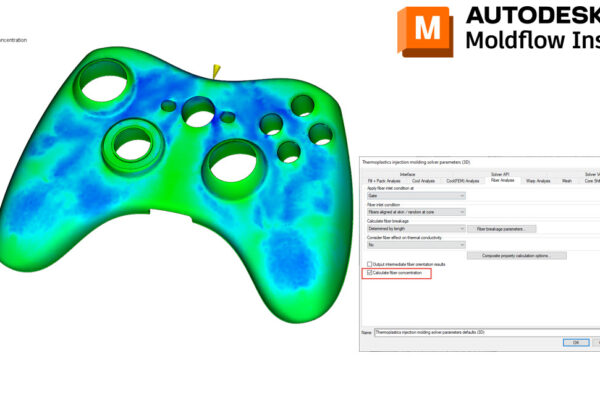

Anytime you select a material that has a fiber filler, Moldflow Insight will select the correct fiber model and generate several fiber plots such as Fiber Orientation, Average Fiber Orientation, and Fiber Orientation Tensor on Elements.

Fiber values in red and closer to 1 are highly orientated in the first principal direction while values in blue and closer to 0.33 are random. Values in green(~0.5-0.6) are somewhat orientated and somewhat random.

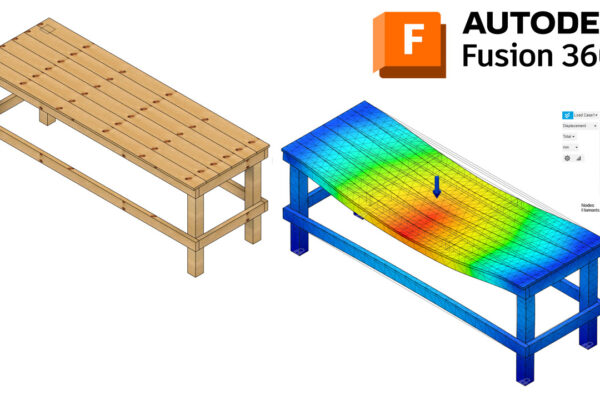

What does this mean to us? Well, how these fibers align will impact shrinkage and can impact our deflection results. If fiber is the leading cause of your warpage headaches – move the gate, change the part thickness, or possibly adjust your fill speeds.

Bonus – If you pick a long glass-filled material – you can also evaluate the fiber length and fiber breakage on your model.