Why running warp in 3D can be useful!

I had a very interesting discussion last week with one of my mentors. We had to agree to disagree on some items but within our discussion came this week’s topic – STRESS!

While I do run some Midplane and Dual Domain analyses occasionally, I am an unapologetic proponent of 3D mesh in Moldflow Insight.

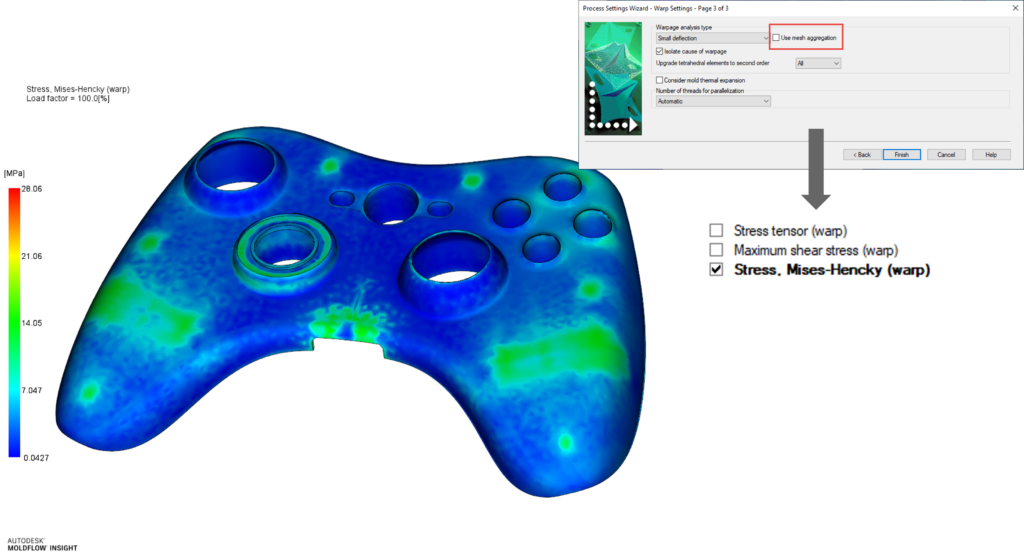

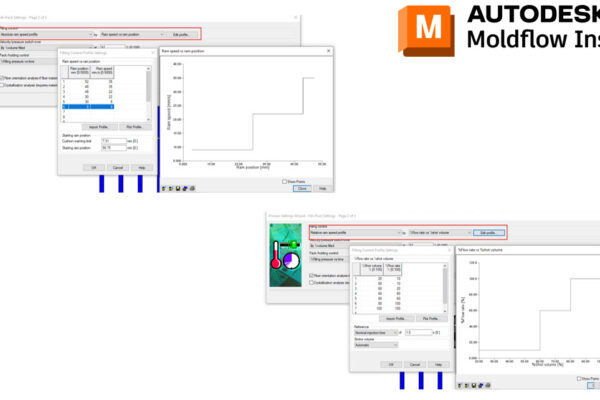

Did you know that if you are running Warp in 3D, you can deselect the Mesh Aggregation option and generate 3 new stress plots?

This is a ductile material so I evaluated the Stress, Mises-Hencky (warp) to ensure the molded-in stresses are lower than the material limits to prevent failures downstream.