Why using the Dimensional diagnostic in 3D can be useful!

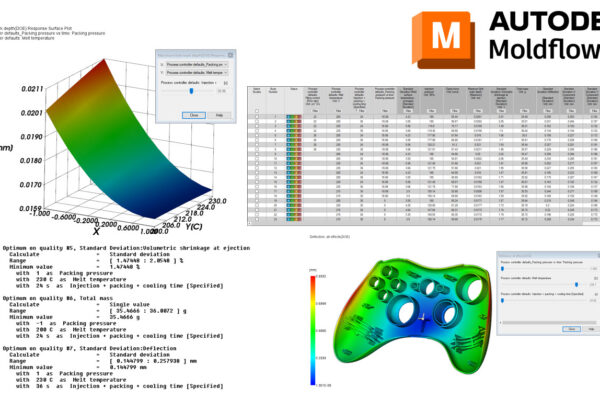

The first rule of plastic part design is uniform wall thickness.

The first rule of plastic part design we break is also uniform wall thickness.

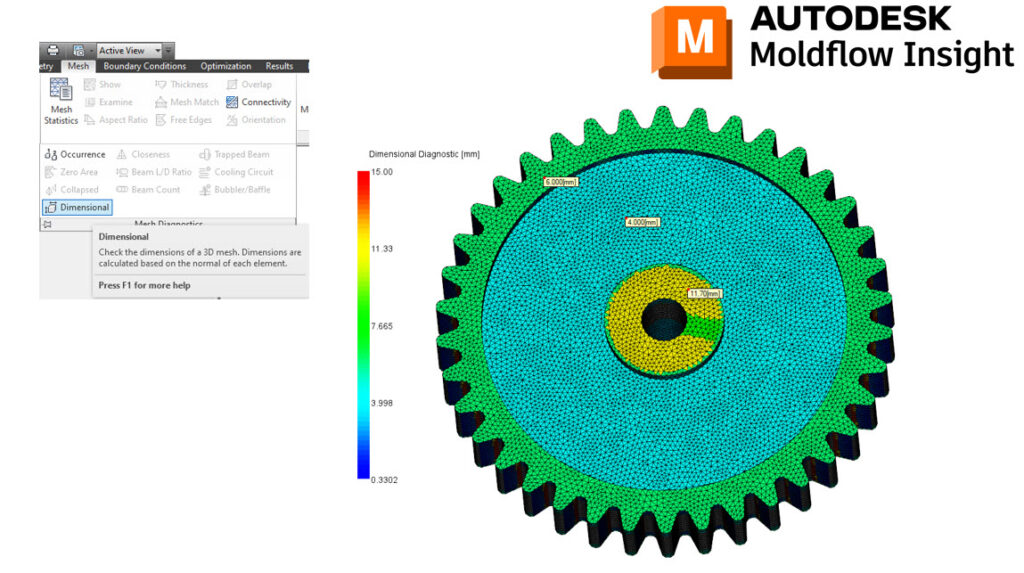

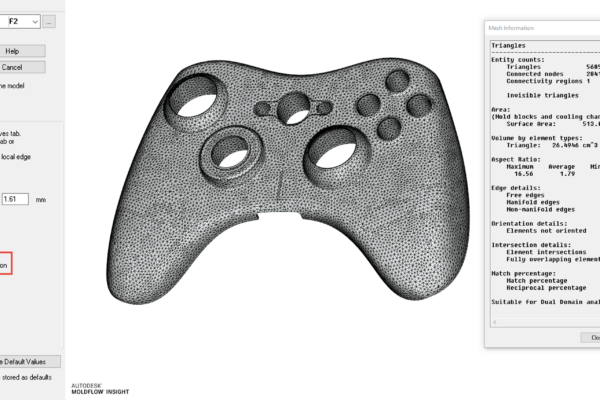

Most people know that we have a Mesh Thickness diagnostic that we can use for Midplane and Dual Domain. Did you also know we have a Dimensional diagnostic that can be used for 3D mesh (Mesh tab – Mesh Diagnostics panel dropdown – Dimensional.

Areas that are thicker will take longer to cool down, have different volumetric shrinkage, and will warp differently than thinner sections.

Have you ever tried using the Dimensional diagnostic in 3D?